HYDROPLUS NEWS

Latest news

Moog’s new X700 Series Servo Cartridge Valves serve as robust throttle valves in electrohydraulic flow control systems, especially those requiring quick dynamic responses and high flows. Typical applications include die-casting, metal sheet forming, and presses, as well as other types of heavy industrial equipment.

The X700 Series Servo Cartridge Valves provide users with numerous advantages over other throttle valves.

The advantages at a glance:

- Fast response time for high machine dynamics

- New flow-optimized design with a significant increase in volume flow rate

- Robust design for operating pressures up to 420 bar

- Higher energy efficiency thanks to low internal leakage

- Maximum flexibility through analog and fieldbus interfaces

- Fail-safe options for applications with the highest safety requirements

Fossil energy sources are becoming increasingly expensive. In addition, the transition to other types of energy is encouraged from the public debate about this and from the government.

Hydroplus, and its sister company Mabotec, have recently switched to the partly self-generation of their electricity supply. With the installation of an area of 812 m2 of solar panels, 136,000 kWh per year of energy is now generated, which is 35% of the total electricity consumption.

This was made possible by the establishment of their own so-called Green Fund, from which more sustainable applications are being financed.

Hydroplus likes sustainable business and contributes this way to the energy transition and cleaner environment.

MOOG is constantly optimizing its products. It is interesting to know that a new Electro-Hydrostatic Actuator System is now available that provides modular building blocks for industrial applications. The most important advantages are energy efficiency and environmental cleanliness. In addition, there is a low noise emission and the ability to handle high forces without backlash. They are customized building blocks based on customer's requirements. More information about this can be found in the datasheets below.

It is emphasized by the engineers at MOOG that the actuator can be built centrally and compactly on the machine or in the installation, so that no large surfaces are required, as often is the case with a Hydraulic Power Unit (HPU).

MOOG has released a new review of its world class Electro-Hydraulic products for the highest machine productivity, which moves your world of hydraulic energy to the best possible level of reliability and efficiency. This new review shows a handy summery of all the electro-hydraulic components which are within MOOG’s assortment.

As quality is one of Hydroplus’ trademarks in manufacturing its hydraulic manifold systems, we also apply MOOG’s products. Hydroplus acts as a reseller of these products as well.

Hydroplus' cooperation with Moog guarantees the application of modern and highest quality components in the Hydroplus hydraulic manifold systems. Regularly, as a result of research, new products are being manufactured by Moog.

A new version of the Moog Radial Piston pump is now available with variable displacements up to 250 cm3 for applications requiring high system pressures up to 350 bar (5.000 psi) such as metal forming machinery and presses, heavy industry and plastics machinery.

The new RKP 250 is the product of choice for highly dynamic control of hydraulic flow and pressure. The pump is available in a high pressure version for continuous pressures up to 350 bar (5.000 psi) and offers full drive-through capability. The pump is designed to be used in open-circuit systems, has a large suction port and a flow-optimized suction path, ensuring robust suction behavior, a high speed limit and low noise. The 9-piston rotary group used in the RKP 250 has the typical minimized piston clearance volumes leading to lowest pressure ripple and best noise emission behavior that is characteristic for this design.

Consistent with the design of the smaller RKP-sizes, the RKP 250 is also equipped with the proven, robust control system with sliding stroke ring. The exclusive use of ferrous metals with hardened, wear-resistant surfaces at the part contacts leads to outstanding longevity of this product line in the field. This design also allows special pump versions for use with HFC and HFD fluids.

Moog offers a modular design concept with a range of different compensator options: Pressure compensator (F2), combined pressure and flow compensator (R1), fixed displacement (B1), dual displacement (N1).

The RKP-D with a highly dynamic electro-hydraulic control (D1 to D8) can easily be configured with the Moog Pump Configuration Software. Status information, set values and actual values are displayed graphically for quick and easy performance monitoring, trouble shooting and tuning.

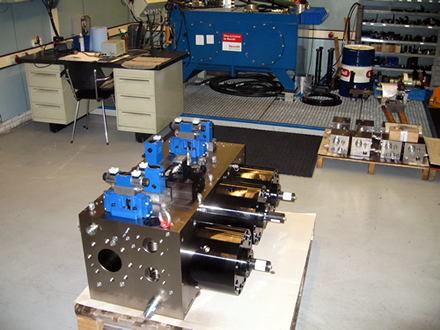

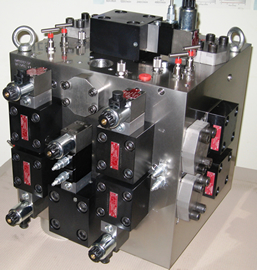

In December 2013, Hydroplus has supplied its largest hydraulic manifold system ever to one of its customers. With a total weight of 4.5 tons, Hydroplus has once again surpassed itself in the production of integrated hydraulic manifold systems.

The hydraulic manifold system was designed in close cooperation with the customer and is now being used as a main part in their hydraulic system for a special piling hammer application in the offshore industry.

The manifold block itself is made of HYT60 (+ 3.1 cert.) steel and was manufactured by sister company Mabotec, specialized in producing large blocks up to 10 tons. The block-system had been assembled with MOOG cartridges and SUN valves.

With the production of this super manifold system, Hydroplus again shows that almost no job is too "heavy" to meet with the demands for very large hydraulic applications.

Hydroplus’ stand has been an interesting attraction for many who have visited the Hannover Messe 2013. Hydroplus exhibited at the Hannover Messe, as it does every 2 years. For a great deal of hydraulic manifoldsystems related parties Hydroplus’ stand was the place to be. Those who have visited the Hannover Messe this year have seen innovative developments on behalf of Hydroplus.

There was special interest in our exposition of a SUN configuration, which showed a 3 step development: the manufacturing process from raw material (HYT60) to a hydraulic manifold and finally to a manifold system used for hydraulic control of the Ampelmann Gangway (www.ampelmann.nl). This configuration embodies up to 56 different SUN valves, which is considered to be a world record regarding a SUN integrated hydraulic manifold system.

Although the company MOOG GmbH was not represented at the Hannover Messe 2013, several of their specialists were dedicatedly present at the Hydroplus booth to display MOOG’s products and to offer support. Visitors have encountered a special synergy between Hydroplus and MOOG regarding their collaboration.

Hydroplus wants to thank everybody who was able to visit its stand at the Hannover Messe. It was a pleasure meeting you. Those who couldn’t witness Hydroplus’ newest technologies are very welcome to visit our factory in Waalwijk !

- best in class flow rates;

- leakage free pressure valve functionality;

- directional and pressure functions for all sizes with full range options (dampening nose, spring forces, shaft seals);

- robust design to create an increased pressure level to 420 bar;

- and proven high reliability of Moog products.

The incorporation and use of these new cartridge valves by Hydroplus again enhances the level of services to our customers within the fluid power industry.

1-11-2012Hydroplus presentation at Water Hydraulics Symposium

As mentioned in our latest news bulitin, Hydroplus, among others, has sponsored the 2012 Dutch Fluid Power Conference. This symposium dealt with the application of water instead of oil as a medium to transmit power

Mr. John Kruis of Hydroplus has addressed the audience with his concepts about water powered hydraulics at the Water Hydraulics Symposium, which have been received with appreciation.

Please click at the link below to get a copy (PDF) of this presentation.

|

Het Hydrauliek SymposiumThe 5th "Dutch Fluid Power Conference" (Het Hydrauliek Symposium) will be organized in the Netherlands on September 13, 2012. This lustrum conference is being arranged in cooperation between the society of Dutch hydraulic experts (Vereniging Platform Hydrauliek) and the federation of Dutch suppliers in the fluid power business (FEDA). Recent developments concerning "Water Hydraulics" are being covered during Het Hydrauliek Symposium. HYDROPLUS is one of the sponsors of "Het Hydrauliek Symposium". Mr. John Kruis from HYDROPLUS is going to address the audience lecturing about Water Hydraulics. We kindly invite everybody to participate. For more information please click on the links below. There is also a registration form to settle your presence at the symposium.

HYDROPLUS wishes you a useful and an instructive participation at the Hydrauliek Symposium! |

|

25 May 2011 NEW........ A BREAKTHROUGH IN THE WORLD OF FLUID POWER WHICH MAY CHANGE PRESENT HYDRAULIC CONCEPTS For the first time ever, HYDROPLUS B.V. has now launched a manifold system which is to use seawater as a hydraulic preliminary fluid. Because of many well-known environmental reasons a strong demand is rising within the offshore industry for clean and environmentally friendly fluids to operate hydraulic systems. In 2009 HYDROPLUS B.V. was invited by IHC-Hydrohammer for a brainstorming session in order to develop a seawater resistant manifold system.  Apart from producing all the necessary components, the method of piloting the cartridges is a special issue. Due to this specific design the cartridges are being operated with normal mineral hydraulic oil. IHC expects a growing market for these systems in the future. We wish them good luck!

|

|

16 May 2011 As in previous years, Hydroplus has again been exhibiting at the Hannover Messe 2011 in Germany, which resulted this time in the best outcome in 10 years. The Hannover Messe is one of the leading international fluid power trade events in the world.

Hydroplus had an enourmous success in terms of interest and response. As a major key player in the world of hydraulic manifolds systems, Hydroplus has shown its outstanding capacity in meeting with the highest technology standards required nowadays. The Hannover Messe 2011 has seriously widened the scope of Hydroplus concerning cooperating associates and dedicated customers. This guarantees Hydroplus’ stability in maintaining its widely recognized level of technology and quality.

Researching new possibilities regarding the use of uncommon solid and fluid components is one of the challenges of Hydroplus and may change present hydraulic concepts. At this moment Hydroplus is researching stainless steel manifold systems. DUPLEX manifolds are produces by Mabotec and special INCONEL cartridges are being applied. Once again it is obvious that the world of hydraulic manifolds systems is driven by just a few leaders in this specific market. Hydroplus has an acknowledged record to be one of these leaders! |

1 July 2009 Hydroplus supplies the biggest hydraulic manifoldsystem in their history.

It concerns a control system with the dimension of 800x650x1050 mm and total weight of approx. 2600 KG.

|

15 juni 2009

Hydroplus heeft een order ontvangen van Bosch Rexroth voor het leveren van manifoldsystemen. De waardering van Bosch Rexroth voor de speciale expertise van Hydroplus heeft geleid tot een overeenkomst voor de engineering en montage/testen van manifoldsystemen die toegepast worden in offshore-installaties. Hierbij levert Bosch Rexroth componenten toe aan Hydroplus en worden de manifolds zelf geproduceerd bij Mabotec BV. Het betreft hier een overeenkomst waarbij de keuze van samenwerking in plaats van concurrentie een voorbeeld mag zijn. Flexibiliteit voorop! |

Waalwijk, 01 maart, 2008

Betreft: Samenwerkingsovereenkomst tussen Hydroplus BV en Vos Hydraulics BV. In het najaar van 2006 kwam de heer Peter Vos ons team versterken. De explosieve groei van orders en tijdelijke afwezigheid van John Kruis bracht ons Hydroplus BV in een niet altijd eenvoudige positie. Dankzij de geweldige inzet van Peter Vos en Henk van Herwijnen hebben wij een en ander in ons bedrijf goed weten op te vangen.. Met John inmiddels weer volop in de running hebben wij momenteel te maken met een dermate groei van de orderportefeuille, dat wij de samenwerking met Peter graag willen continueren middels een langdurige samenwerkingsovereenkomst. Peter Vos heeft onlangs zijn eenmanszaak omgezet naar Vos Hydraulics BV. Het is onze intentie om met dit bedrijf onze specialiteit en service op het gebied van Geïntegreerde Hydrauliek Manifold Systemen verder te versterken.

|

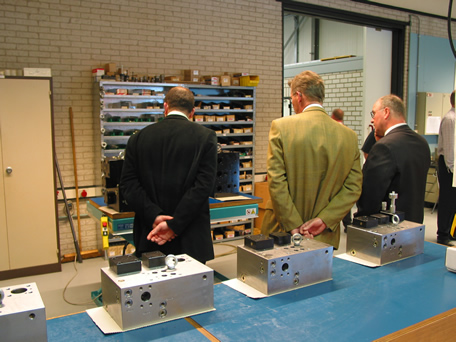

| HYDROPLUS ONTVANGT VERENIGING PLATFORM HYDRAULIEK |

Met enige regelmaat brengt de Vereniging Platform Hydrauliek een bezoek aan een aan de branche gelieerd bedrijf of instelling. Donderdagmiddag 26 april trad Hydroplus op als gastheer voor ruim dertig bij de vereniging aangesloten leden. Het werd naast een gezellig, bovenal een vaktechnisch interessante samenkomst.

Tijdens de rondgang door onze moderne bedrijfsruimten in Waalwijk ontspon zich op de test- en montageafdeling van Hydroplus een discussie over de reinheid van het product manifold bij aflevering aan de klant. De actualiteit van dit onderwerp zorgde voor een levendige discussie. Wat Mabotec betreft wordt er naar geaccepteerde norm gereinigd en worden de manifolds in principe klaar voor montage toegeleverd. Er zijn echter nogal wat hydrauliek verwerkende bedrijven die een extra in- en uitwendige reiniging van alle te monteren componenten voorstaan. Het blijft altijd de vraag welke reiniging vereist wordt en hoe hoog de daar aan verbonden kosten en wie daar uiteindelijk de rekening voor wil betalen. Ook enkele door ons toegepaste speciale cartridges trokken de aandacht en werden uitvoerig door de platformleden besproken. Hydroplus, in de persoon van John Kruis, beschikt over een uitgebreide expertise op het terrein van deze specialistische techniek. De door ons toegepaste producten van Moog-Hydrolux behoren tot de absolute top binnen de cartridgetechniek.

De leerzame en geanimeerde middag werd volgens goed Brabants gastheerschap afgesloten met een hapje en een drankje. Geïnteresseerd in een uitgebreide rondleiding door onze bedrijven, neem contact op met John Kruis, tel. +31 (0) 416 352045 en john.kruis@hydroplus.nl Voor meer informatie over de Vereniging Platform Hydrauliek en haar activiteiten zie www.platform-hydrauliek.nl |

HYDRPLUS EXHIBITING AT HANNOVER MESSE 11th-15th April 2005, Hannover, Germany |

|

Together with sister Company Mabotec b.v., Hydroplus will be presenting many interesting concepts, however the core theme will be the ‘design and manufacture of hydraulic manifold systems’. In association with Hannover Consultancy, Hydroplus’s stand will be of open-plan design with many interesting exhibits, including a manifold weighing over two thousand kilos. Visitors to the stand will obtain professional guidance and advice on hydraulic manifold systems, particularly in Hydroplus’s specialist field of cartridge valve systems. For further information concerning Hydroplus or our presence in Hannover, please email john.kruis@hydroplus.nl We look forward to seeing you!

|

|